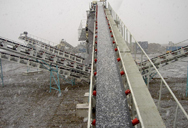

gas conditioning tower of kiln basalt crusher

Gas Conditioning Tower (GCT) - FLSmidth

Our gas conditioning towers cool exhaust gases from cement plant systems, such as the preheaters or kiln bypass systems, before they are conveyed to mills and filters. There

اObtener precio

(PDF) Water and power consumption reduction by gas

2019.6.13 PDF Gas conditioning tower (GCT) is a vital equipment in cement industries. The main principle in this equipment is evaporative cooling, i.e. reducing...

اObtener precio

cement gas conditioning tower design calculations

gas entry into baghouse,ESP,heat exchangers,kilns and more.The Key to Effective Gas Conditioning and Cooling is Control • High efficiency FloMax® air atomizing nozzles

اObtener precio

(PDF) Corrosion Assessment of Gas Conditioning Tower in

2020.4.5 PDF This report discusses on the type of corrosion mechanism the GCT exposed to and theoretical proposal to mitigate. Find, read and cite all the research you

اObtener precio

The generation of power from a cement kiln waste gases: a case

gas temperatures has to be cooled through passing through a gas conditioning tower (GCT) before directing to the vertical raw mill and coal mill for drying the inputs. This also

اObtener precio

Effective Temperature Control for Cement Kiln Off -Gases

The main gas conditioning tower of a large cement manufacturer measured 23' diameter. At an effective height of 70' the residence time was 7-8 sec. The gas flow of 240,000

اObtener precio

modern gas conditioning tower in cement industry

gas conditioning tower of kiln basalt crusher, Home > Crusher Solution 13 > modern gas conditioning tower in cement industry Print Email modern gas conditioning ...

اObtener precio

Gas Conditioning Tower Of Kiln Basalt Crusher

2019.9.25 The cement kiln. The raw meal is fed in at the top of the preheater tower and passes through the series of cyclones in the tower. Hot gas from the kiln and, often,

اObtener precio

Spray Nozzles Control Analysis Fabrication - LEHENGOAK

GAS VOLUME 250,734 acfm (426,000) Nm3/hr INLET GAS PRESSURE 514° F (268° C) OUTLET GAS PRESSURE 302° F (150° C) TOTAL LIQUID SPRAYED 63.4 gpm (240

اObtener precio

copper crusher: gas conditioning tower of kiln

The fibre reloading process coded in Syria crusher brands laboratory is actually a two-step practice. First, calcium supplements hydroxide is actually combined into pulp fibres. Then

اObtener precioMas noticias

- 6 s mesa vibradora oro para la venta mesa vibratoria para la venta

- equipo de trituración de piedra inglaterra

- cemco cone crusher kapasitas 1500

- circón planta de beneficio de arena

- piedra distribuidor de la maquina trituradora de la mineria Gulin uae

- productos de agitador de la pantalla

- molino de martillo para el carbon

- piedra guatemala trituradora s

- maquina de anillo de piston de molienda

- centrifuga de oro para la venta

- máquina electromecánica molienda

- 2012 caliente la venta molino de bolas

- trituradora de carbón en chile

- precio usado de la trituradora de dolomita en bolivia

- venta planta trituradora venta Aug

- balon peso molino de bolas

- equipamientos para extraer el granito

- molinillo de una mquina para el hogar natinol

- la minería de oro de equipos móviles

- trituradoras de esquila, Videos De Trituradora En Colombia

- secadoras de piedra en los molinos

- trituradoras de piedra en uttar pradesh arena haciendo piedra cantera

- fabricante de molinos indonesia

- stone crusher used for sale in usa

- cs series high efficiency spring cone crusher

- que lugar tiene una trituradora de buen punto

- fabricante trituradora de rodillos sudáfrica

- top 10 table top wet grinders

- chancadoras de mandíbula para piedras

- trituración de mineral de cobre a tanto alzado y la multa