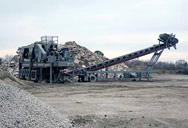

impact during the construction of the milling plant

Environmental Impact Characterization of Milling and

2012.1.1 Had the MRR during the feature construction been on the order of 75 mm 3 /s or greater, the variance in the model error is hypothesized to be even lower. The range of the error amongst the features shows a significant fluctuation.

اObtener precio

Impact of milling machine parameters on the properties of

2021.11.8 Hypothesis 1: Binder ages during milling due to the high temperature of the milling picks;-Hypothesis 2: Aggregate angularity increases during milling due to new

اObtener precio

ENVIRONMENTAL IMPACT ASSESSMENT OF SETTING UP A MAIZE MILLING PLANT ...

ENVIRONMENTAL IMPACT ASSESSMENT OF SETTING UP A MAIZE MILLING PLANT PREPARED BY FRED MMBOLOLO. fred M'mbololo. experienced farmers and

اObtener precio

Impacts of milling duration on construction and

2022.9.1 Impacts of milling duration on construction and demolition waste (CDW) based precursor and resulting geopolymer: Reactivity, geopolymerization and

اObtener precio

Study on the Milling Machinability of Bamboo-Based Fiber

2023.9.21 During the milling tests of recombinant bamboo, we observed surface carbonization and end splitting as common defects, specifically occurring at θ = 90°.

اObtener precio

Effect of aging and temperature on milling-induced stresses and cracks ...

2021.12.27 Also, the “chipped” area becomes larger as the material ages (0 to 60 to 120 months) and the temperature decreases (from 60 °C to 25 °C). Clearly, the asphalt

اObtener precio

Milling operations: Considerations for future mill designs

2021.10.25 It is the behavior of the wheat and monitoring of the wheat and mill stock properties that may in the future have a greater impact on the gradual reduction process

اObtener precio

Applied Sciences Free Full-Text Recent

2022.9.16 Compared with conventional milling (c-milling), p-milling reduced the calcination temperature due to synergistic effects between rapid heating by plasma and impact stress of milling thereby improved the

اObtener precio

Model Study of Mechanicochemical Degradation

2023.1.11 The energy transfer model is aimed at identifying how ball-milling energy is transferred from the ball-milling medium to the material particles during collision, and the impact of ball-milling energy on the ball

اObtener precio

Micromachines Free Full-Text Effect of Milling

2023.1.15 According to the influence of the axial cutting depth on the tool displacement acceleration conditions during milling, the stability of the milling process is remarkably influenced by an increase in the cutting

اObtener precio

Bioengineering Free Full-Text Fine

2019.11.6 The use of lignocellulosic plant biomass as an alternative to fossil feedstocks for chemistry, energy and materials often involves an intense dry comminution step, for which the energy consumed can vary

اObtener precio

Milling Process - Definition , Milling

2 天之前 Milling is a process performed with a machine in which the cutters rotate to remove the material from the work piece present in the direction of the angle with the tool axis. With the help of the milling machines one

اObtener precio

Wet Milling: The Basis for Corn Biorefineries - ScienceDirect

2019.1.1 The wet milling process is designed to efficiently take corn apart and purify its constituents (starch, oil, protein, and fiber), making them suitable for use as human and animal food ingredients, industrial products, or as feedstocks for converting into other value-added products (Anderson and Watson, 1982).Many corn processors have likened corn

اObtener precio

Mechanical milling assisted by electrical discharge Nature

2002.9.12 Mechanical milling is an effective technique for the preparation of fine metallic and ceramic powders and can also be used to drive a wide range of chemical reactions. Milling devices include ...

اObtener precio

Milling Process of Starch SpringerLink

2018.9.20 Abstract. Milling of cereal grains is a very important process for cereal and feed industry. It is accompanied with starch granules damage, starch crystalline structure disruption, and starch molecules change, and therefore performance of the finished products is subject to milling process. This chapter reviews the development of commercial and ...

اObtener precio

Producing Metal Powder from Machining Chips Using Ball Milling

2023.6.27 During the ball-milling process, the metastable anatase TiO 2 undergoes crystal structure disintegration due to the intense impact and friction forces. This is accompanied by a rise in local temperature (ranging from 160 to 200 °C) [ 121 , 122 ].

اObtener precio

The impact of innovative technologies in construction

2023.3.28 As construction activities become more intensive in developing countries, increasing improperly managed construction and demolition waste (CDW) brings serious environmental impacts. Recycling is a beneficial way to dispose of CDW that reduces environmental impact and brings economic benefits, especially for concrete. China is the

اObtener precio

Understanding the Effect of Granulation and Milling Process

2020.4.30 Milling is an essential unit operation used for particle size reduction in solid oral dosage manufacturing. The breakage of particles in a comil is due to the intense shear applied on the particles between impeller and the screen. Breakage also occurs due to the impact from a rotating impeller. Particles exit the mill based on their size relative to the

اObtener precio

Foods Free Full-Text The Effect of Wet Milling and

2020.11.27 The particle size distribution of wheat bran as a function of time or number of passes during (A) cryogenic milling on a laboratory scale, (B) wet milling on a laboratory scale, (C) cryogenic milling on a large scale, (D) wet milling on a large scale. d10, d50 and d90 correspond to the diameter where 10, 50 or 90% of the distribution has a ...

اObtener precio

Life Cycle Assessment of an Integrated Steel Mill

2021.3.19 The current dependency on steel within modern society causes major environmental pollution, a result of the product’s life cycle phases. Unfortunately, very little data regarding single steel production

اObtener precio

Engineering process and cost model for a conventional corn wet milling ...

2008.1.1 A small amount of sulfur is consumed in the wet milling process to produce the SO 2 described in Section 2.2. The amount of sulfur consumed and its cost are included in the model. The total cost of sulfur is less than US$ 20,000 year −1. Natural gas, steam and electricity are the utilities required for the wet milling process.

اObtener precio

Silo design and construction - Milling and Grain

2023.6.2 Cereal and rice processing plants such as flour mills, feed mills, seed plants, rice mills, malting plants, breweries, etc. always include the following relevant components: Daily silos; Dosing silos; Silos for

اObtener precio

Materials Free Full-Text Milling of an Al/CFRP Sandwich

2020.8.7 In this study, the effect of cutting parameters on the quality of an Al/CFRP sandwich structure (aluminium alloy–carbon fibre reinforced polymer) after milling with uncoated and TiAlN-coated tools was examined. The results of the cutting force were also investigated. The research was conducted in a VMC 800 HS vertical machining centre

اObtener precio

A modern, efficient milling sector 2021-02-12 World Grain

2021.2.12 Sosland Publishing’s 2021 Grain Milling Annual puts the total number of wheat flour mills in the United States at 160, down six from 2019. The states with the greatest number of mills are Pennsylvania with 13, California with 12 and Kansas with 11. The total US daily capacity in 2021 is 1,518,123 cwts, down 56,940 cwts from the

اObtener precio

Effects of Different Grinding Media and Milling Conditions

2022.12.11 Different milling conditions, such as wet or dry, and use of different grinding media have a great impact on the flotation performance of sulphide minerals. In the present study, the effects of wet and dry grinding and the use of different grinding media, such as mild steel (MS) and stainless steel (SS), were investigated on a Cu-sulphide ore.

اObtener precio

ENVIRONMENTAL IMPACT ASSESSMENT OF SETTING UP A MAIZE MILLING PLANT ...

ENVIRONMENTAL IMPACT ASSESSMENT OF SETTING UP A MAIZE MILLING PLANT PREPARED BY FRED MMBOLOLO Page 1 of 47 ABSTRACT An application for development permission to the county, NEMA as well as other approving authorities regarding eager of putting up a maize milling plant in an already built godown on a plot in

اObtener precio

Foods Free Full-Text Stone Milling versus Roller Milling in

2021.12.31 Wholegrain soft wheat flours can be obtained by either roller milling or stone milling. In this paper, we report on the continuation of a study aimed at analysing compositional and technological differences between differently milled wholegrain flours. Eight mixes of soft wheat grains were stone milled and roller milled and the milling

اObtener precio

(PDF) Rod Mill Product Control and Its Relation to

2022.1.30 A laboratory-scale tumbling rod mill was designed for this study, and six operative parameters were tested and analyzed in order to detect the main influences on the mill product, attending to ...

اObtener precio

Environmental Impact Of Milling Machine - Crusher Mills

Impact During The Construction Of The Milling Plant, details liming crusher machine company give you the all-round service.Impact During The Construction Of The Milling Plant. Draft Generic Environmental Impact Statement On Uranium

اObtener precio>> Next: Mineria Dolomita Utilizado Molienda Molino De Rodillos

Mas noticias

- el proceso que pasa a travs de la piedra caliza

- Trituradora De Oruga En Arequipa

- proceso de produccion de postes de hormigon

- planta de procesamiento de mineral de manganeso completa

- costo actual de la trituradora de molino de bolas

- Educación Física Concepto

- facil instalacion de la celda de flotacion del eje

- Fondos Escritorio Etiquetas

- planta procesadora de hielo

- lo que es un molino de arcilla

- de moler maiz en panama

- Maquinas Para Materiales

- Alquiler Trituradora Pe

- trituradora de la mineria del carbon de segunda mano en zimbabwe

- equipo de diagrama planta

- trituradora de piedra Shaoguan

- pantalla molino de cono fabricante de porcelana farmaceutica

- tipos de piedras en la cantera tenemos

- planta de trituracin portatil de piedra

- fuentes de aserradero de china

- utilizado tipo oruga trituradora port til para la venta

- segunda mano electricas

- planillas de mantenimiento de trituradoras

- olla presión ofertas

- maquina chancadora de piedra mercadolibre compro

- flujograma de proceso de extraciion de carbon

- molino de bolas de procesamiento de oro machnie

- el hierro en el cuerpo humano

- Kefid VSI trituradora movil

- trituradoras de piedra de arena de piedra singapur