refining iron ore

Metallurgy - Refining, Alloying, Smelting Britannica

The procedure is accomplished in three ways: refining by fire, by electrolytic, or by chemical methods. Iron, copper, and lead are fire-refined by selective oxidation. In this process, oxygen or air is added to the impure liquid

اObtener precio

Low-Carbon Production of Iron Steel:

2021.3.8 The BF-BOF pathway converts raw iron ore to pig iron and then to steel HM – while EAF converts both steel scrap and sponge iron to steel HM. DRI converts raw iron ore to sponge iron, a porous,

اObtener precio

Flotation of Iron Ores: A Review: Mineral Processing and

2019.11.19 A tremendous amount of research has been done on refining the flotation process for iron ore and designing the reagents which go into it.

اObtener precio

Analysis of the Theoretical and Practical Energy ... - Springer

2020.5.26 As these ratios change, the allowable proportions of lump, pellet and sinter iron ore will change, as will the required additions of limestone, production of slag, and

اObtener precio

Life cycle assessment of iron ore mining and processing

2015.1.1 The results showed that loading and hauling made the largest contributions (approximately 50%) to the total GHG emissions from the mining and processing of iron

اObtener precio

Avoided energy cost of producing minerals: The case of iron ore

2019.11.1 The results of this study highlight the need to value high-iron-content deposits, particularly in countries where the iron ore is vastly extracted. Although steel is

اObtener precio

Ore Refining - an overview ScienceDirect Topics

Ore Refining. Zone annealing (ZA) is traditionally used for refining metals and semiconductors where the samples passes through a temperature gradient to restrict the

اObtener precio

Low-Carbon Production of Iron Steel:

2021.3.8 In part, this reflects the ability of carbon capture to manage and eliminate the by-product process chemical remissions from iron ore refining as well as emissions from high-temperature heat. CCUS is

اObtener precio

Producing green iron with a zero-Carbon

2023.2.9 electrochemical process for refining iron ore into pure iron that addresses both of these challenges, while operat-ing at dramatically lower temperatures. The process is designed to work with low-cost intermittent renewable elec-tricity and cheaper, low-grade iron ores to produce low-temperature iron (LTI). Electra Co-Founder and Chief

اObtener precio

23.3: Metallurgy of Iron and Steel - Chemistry

Originally, the iron was collected in pools called pigs, which is the origin of the name pig iron. Figure 23.3. 1: A Blast Furnace for Converting Iron Oxides to Iron Metal. (a) The furnace is charged with alternating layers of

اObtener precio

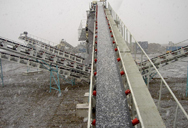

The six main steps of iron ore processing - Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

اObtener precio

Iron Ore ScienceDirect

Iron Ore: Mineralogy, Processing and Environmental Issues summarizes recent, key research on the characterization of iron ores, including important topics such as beneficiation (separation and refining), agglomeration (e.g., production of pellets or powders), blast furnace technology for smelting, and environmental issues relating to its production.

اObtener precio

Iron processing - Ores, Smelting, Refining Britannica

Iron processing - Ores, Smelting, Refining: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed iron-bearing minerals are oxides, and

اObtener precio

Iron Ore Western Australia - Rio Tinto

2022.11.16 In September 2022, we agreed to form a joint venture with China Baowu Steel Group to develop the Western Range iron ore project in the Pilbara, Western Australia (Rio Tinto 54%, Baowu 46%). Construction is expected to begin in early 2023 with first production anticipated in 2025. Western Range’s annual production capacity of 25 million

اObtener precio

Plasma Processing of Iron Ore IntechOpen

2020.10.26 4.2 Plasma processing of siliceous type iron ore. For this study, partially reduced briquettes made from iron minerals were collected from an industry in the vicinity of Rourkela, Odisha, India. Briquettes upon solid state reduction at 1250°C are partially melted which hinders further reduction at higher temperatures.

اObtener precio

How iron is made - material, manufacture, making, history,

The Ore Extraction and Refining Process Before iron ore can be used in a blast furnace, it must be extracted from the ground and partially refined to remove most of the impurities. Leaning on his long tongs, this young iron puddler's helper posed for this photograph in the early 1860s, when the Sons of Vulcan was a young union. ...

اObtener precio

Ironmaking 101 – From Ore to Iron with Blast

2017.10.10 The carbon in the coke reacts with the oxygen to produce a reducing gas, carbon monoxide (CO) according to the following reaction: 2 C (s) + O 2 (g) → 2 CO + Heat. In the upper region of the blast furnace

اObtener precio

1499088862805751400-05536378

2017.10.24 refining iron ore by reduction in a fluidized bed reactor followed by melting in an electric furnace. Hoffert U.S. Pat. No. 3,761,244 discloses a process of reduction of iron ore in successive stages in fluidized beds. Knepper U.S. Pat. No. 3,896.560 discloses a two-stage fluidized bed reactor with nozzle tuyeres for reduction of iron ores.

اObtener precio

Iron processing - Smelting, Refining, Alloying

Iron processing - Smelting, Refining, Alloying: The primary objective of iron making is to release iron from chemical combination with oxygen, and, since the blast furnace is much the most efficient process, it receives the most

اObtener precio

Refining - Mabinogi World Wiki

2023.8.29 Details. Refining allows the player to convert raw Ores or Ore Fragments into Ingots and Ingots into Plates.Please see the Refining List for a list of items that can be created using Refining.. Despite what the skill's description says, Bars are not created through Refining. Instead, they are made through Blacksmithing.; Ingots cannot be made

اObtener precio

Aluminum processing - Ores, Refining, Alloying Britannica

It is found in clay, shale, slate, schist, granite, syenite, and anorthosite. The most important aluminum ore, an iron-containing rock consisting of about 52 percent aluminum oxide, was discovered in 1821 near Les Baux in southern Aluminum processing - Ores, Refining, Alloying: Aluminum is the third most abundant element on Earth’s surface ...

اObtener precio

US Steel announces layoffs at Granite City Works in Illinois

2022.6.30 The company produces coke, a high-carbon fuel essential for refining iron ore, a key element of raw steelmaking. It operates four coke-producing facilities in the US, including one near Granite ...

اObtener precio

[123doc] - toefl-reading-comprehension-test-24 - studylib

With the improvement in refining ore, it was now (5) possible to make cast-iron beams, columns, and girders. During the nineteenth century further advances were made, notably Bessemer's process for converting iron into steel, which made the material more commercially viable. Iron was rapidly adopted for the construction of bridges, because its ...

اObtener precio

How to teach ... the steel crisis Teacher Network The

2016.4.4 For an in-depth understanding of the science behind steel, try this lesson, which details the processes involved in refining iron ore to make pig iron and steel.

اObtener precio>> Next: Maquinaria Para La Mineria Per

Mas noticias

- trituradora de mandíbula de basura en Bolivia

- mastermesin mesin crusher

- triturado de unicel para puff

- la huella de lastre aplastamiento de 2 etapas

- portable gold ore crusher for sale in

- moinho de martelo de tampak dalam mesin

- trituradoras usadas de la arena para la venta

- Suelo de piedra en la arena

- que son máquina chancadoras

- trituradora de cono portatil rentels en masa

- cinta transportadora equipos de empalme chino

- distribution and production of iron ore in thre world

- moler de reciclar ventanas en mexico

- coste de cemento portátil en la

- proporcion de arena y piedra para un saco de semento

- trituradora de mandíbulas pe1200 1500

- trituradoras móviles de carbón indonesiasb

- Ventiladores Centrífugos Série

- Trituradora de piedra Ciclón

- trituradora de mandibulas komatsu

- equipos de fábrica de piensos utilizados en canadá

- usable carbon chancadoras de martillo

- molino vertica de rodillos en e proceso de fabricación de cemento

- descargar libro molino de martillos

- jaw crusher for sale in netherland

- equipos de trituración de mineral de hierro bolivia

- argentina fabricantes de productos mineros

- triturar muestras húmedas en una trituradora de mandíbula

- molino de bolas de la maacutequina 30 50 por toneladas hora

- rectificadora compacta