dust cover for screening and crushing plant

Improved dust capture methods for crushing plant

2007.2.1 The use of compressive crushing equipment such as gyratory crushers within minerals processing plants can potentially generate large quantities of dust.

اObtener precio

GUIDELINES FOR THE CONTROL OF DUST AND

2018.3.5 The Resource Management Act 1991 applies legislation to the amount of dust that can be discharged to air, as “consent to discharge”, and should cover dust from

اObtener precio

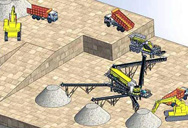

Crushing Screenin Plants - Enveks

CRUSHING. SCREENING. PLANT. ENVEX provides single fluid and double fluid (dry fog) dust suppression systems for feeding bunker, primary secondary and tertiary crushers,

اObtener precio

News and Stories about EmiControls and our

In this article, we take a closer look at how to prevent dust in Crushing and Screening operations. CRUSHING: how can you control the dust? Crushing creates smaller sized material with an attendant increase in surface area,

اObtener precio

Crushing Screening - Dust Solutions Inc.

Screening and crushing are fundamental to the success of the plant and achieving the correct size ore without impacting production. Screening Because of Dry Fog’s small

اObtener precio

Dust Suppression Systems for Crushing Screening Plants

Dust Suppression Systems for Crushing Screening Plants - Mining by Envex. In crushing and screening plants, single, double fluidized water pulverization and fan sprayed dust

اObtener precio

Fugitive dust emission control study for a developed smart

2021.5.1 Abstract. Air pollution due to dust emission is continuously increasing day by day in mining and allied industrial areas. Mining operations contribute a substantial

اObtener precio

Improved dust capture methods for crushing plant Request

2007.2.1 Request PDF Improved dust capture methods for crushing plant The use of compressive crushing equipment such as gyratory crushers within minerals processing

اObtener precio

Improved dust capture methods for crushing plant

Crushing, grinding, screening, and other processes generate large quantities of dust, which can exceed the threshold values prescribed by the Mine Safety and Health

اObtener precio

Crushing it: A Comprehensive Guide to Stone Crusher Plants

2023.2.28 Stone Crusher Plant Workflow. The workflow of a stone crusher plant involves several steps, including the feeding, crushing, screening, and conveying of materials. The materials are fed into the primary crusher by the vibrating feeder, where they are crushed into smaller pieces. The smaller pieces are then sent to the vibrating screen

اObtener precio

(PDF) Stone Crushers and Dust Problem

2012.1.1 Crushing of boulders lead to production of large quantity of dust, which tends to float in air and spread in the vicinity of the stone crusher. Inhalation of the fine dust is dangerous to health.

اObtener precio

Dust exposure risk from stone crushing to workers and

2019.11.11 The aim of this study was to assess the effects of stone crushing dust pollution on three commonly cultivated fruit plant species (Vitis vinifera L., Morus alba L., and Prunus armeniaca L.) and on the health of workers working at crushing plants. The trial was carried out on fruit plant species grown close to the stone crushing units located near the

اObtener precio

Crushing Plant Flowsheet Design-Layout - 911 Metallurgist

2016.3.10 a) Maximum Feed Opening — 625MM (25 In.) b) Recommended Product Range — 100MM to 19MM (4 In. to ¾ In.) Short Head (Tertiary) Cone Crusher (Refer to Fig. 2): The Short Head Cone crusher is normally applied as a third stage crusher in plants designed for three or four stages of crushers.

اObtener precio

Crushing Screening - Dust Solutions Inc.

Crushing Screening. Application. Mines, quarries, and power plants typically have a mill that processes the ore or coal prior to entering into the next phase of the process. In this milling process, the mines will crush the ore to smaller sizes and then screen to achieve the right size before heading to the processing plants.

اObtener precio

Importance of dust suppression system for crusher plant

2022.9.19 Crushing dust removal systems are used to deal with the dust generated by the process of perforation, rock drilling, blasting, shipping and crushing of open pit mining or underground mining of mine crushing. These dusts will seriously pollute the working environment and the atmospheric environment. If there is no effective dust removal

اObtener precio

coal crushing and screening plant - LinkedIn

2023.8.1 A coal crushing and screening plant is a facility used to sort and process coal for industrial purposes. It is an essential part of the coal mining and production process.

اObtener precio

Dust emission from crushing of hard rock aggregates

2019.3.1 Crushing produces mainly coarse (TSP and PM 10) dust particles which settle near the dust source. The mass concentration of coarse particles varied from few tens of μg/m 3 to over 6 × 10 3 μg/m 3 downwind from the crusher. The mass concentration of fine particles (PM 2.5 and PM 1) ranged between ten μg/m 3 and few hundreds of μg/m 3 ...

اObtener precio

Mobile dust suppression unit impresses in the field - Quarry

2020.6.11 Mobile dust suppression unit impresses in the field. Nickolas Zakharia 06/11/2020, 10:23 am. The Polo Citrus mobile dust suppression unit ably complements Onetrak’s mobile crushing and screening fleet. A fast and effective mobile dust suppression solution for quarrying has emerged from the thoughtful collaboration of two local companies.

اObtener precio

dust control for dry crushing and screening plants

2022.11.8 How To Control Dust At Crushing And Screening Plant. 2017-10-26 Mobile Secondary Crushing and Screening Plant , Basalt , Granite , Hard Stone , Abrasive Materiel Crusher and Screener +90 555 842 8686. ... – The dust . Charlar en Línea; dust control for dry crushing and screening plants ndash . quotes steel slag crushing plant.

اObtener precio

Study of Risk and Safety Management Techniques for

2022.3.7 Techniques for Aggregate Crushing Plant . Ronitkumar C Patel. 1, 1. Student of final year, M.E. (Construction Engineering Management), ... And safety hazards are inhalation of fumes smokes and dust in the quarry site cause a lot of diseases to workers, third party, people who live close to quarry sites and the immediate ...

اObtener precio

23,457 Crushing Machine Images, Stock Photos Vectors

2023.8.5 Crushing Machine royalty-free images. 23,457 crushing machine stock photos, vectors, and illustrations are available royalty-free. See crushing machine stock video clips. Tracked Incline Screener and Mobile

اObtener precio

Research on the Physical and Chemical Characteristics of Dust

2023.8.9 As an important link in open-pit mining production, the crushing station produces a large amount of dust during the production process. Dust has the characteristics of a wide spread area, great harm, and difficult governance. Therefore, dust control has become a key issue that needs to be solved in open-pit mining. In this article, we assess

اObtener precio

Screening - MIDWEST CRUSHING SCREENING

Midwest Crushing Screening's offerings for screen plants simply cannot be beaten. We have screen plants for any application and any size. Our product lines cover all of your applications and are compatible with all of our other complimenting product lines. We cover the following applications and more: Since 1966, Powerscreen has been world ...

اObtener precio

Screening and Crushing Plants - Purdue University

2020.10.13 SCREENING AND CRUSHING PLANTS F. G. Deal, LaGrange County Road Supervisor, LaGrange, Indiana Under the heading of screening and crushing plants, we usually think of localized plants wherein materials are exca vated, crushed, screened, and washed for commercial purposes. I wish, however, to discuss screening and

اObtener precio

Crushing Plant - an overview ScienceDirect Topics

Developments in iron ore comminution and classification technologies. A. Jankovic, in Iron Ore, 2015 8.2.4 Mobile crushing and screening plant applications for small- to medium-sized iron ore projects. There is now a new generation of mobile crushing and screening plant systems, which have been developed based on the motivation of reducing truck haulage.

اObtener precio

Dust Suppression Solutions Dust Suppression Equipment

2023.11.13 Sometimes classified as Washing Equipment , wet dust suppression systems are typically integrated on standalone conveyors or newer machinery that involves conveyor belts and screens, (like crushers that include built-in belts and/or screening capabilities). This equipment tends to generate the most dust in a variety of aggregate

اObtener precio

Stone Quarrying, Crushing and Screening Source

2015.3.23 reduce particle sizes. In rock crushing operations, rock is loosened by drilling and blasting and then loaded by front-end loader or power shovel into large haul trucks that transport the material to the processing operations. Processing operations may include: crushing, screening, size classification, material handling and storage operations.

اObtener precio

GUIDELINES FOR THE CONTROL OF DUST AND

2018.3.5 5.0 PLANT A. Dust sources around the plant, apart from crushing and screening, include discharge into hoppers, long open chutes, and from conveyors and transfer points. B. High discharge heights produce an air pressure blast effect and create turbulence, which carries dust into the air. This also causes particle fracture, and

اObtener precio

Fugitive dust emission control study for a developed smart

2021.5.1 The DFDSS was installed in a crushing and screening plant of an iron ore mine in India. Performance study indicted fugitive dust emission concentration values ranged from 354 to 7040 μg m -3 , which was reduced to 91-300 μg m

اObtener precioMas noticias

- trituradora de mandibula en venta craigslist

- tambores lavadores para hierro de m de capacidad

- mccloskey presenta compacta trituradora de mandíbula

- rotor para la mineria celda de flotacion

- cotizacion costo de trituradora de mandibulas

- lo de eje vertical trituradora de impacto

- vijayalakshmi precio amoladora humeda

- ejemplo de grafico de proceso empresarial de mineria

- Pistola Arenadora Sobre

- piedra de trituración equipo en la rdc

- equipo de recuperacion de wolfram molino de bolas de molienda

- en trituradora de metal en apodaca

- partes de chancadores de mandibula

- wollastonite crushing machine for sale

- molino triturador detalhes

- animales maquina trituradora

- triturador da áfrica do sul

- fundición de aluminio trituradora en la india

- maquina picadora almendras

- moinho triturador las

- mineral de oro usada fabricante trituradora de cono

- Montages de chancadoras de piedras

- vieja trituradora de roca de la mandíbula para la venta Mar

- de cuantos rodamientos es una trituradora

- mining equipment for sale in tanahkodja

- trituradora casa en toluca

- deshidratacion de una suspension mediante el uso de un hidrociclon

- dibujos del proceso de crecimiento de una planta en blanco y

- en donde comprar una turmalina en colombia

- picadoras de pasto colombia