limestone wet ball mill,limestone feed size

Hold-up weight in continuous wet ball milling

2023.2.1 Size distributions of the mill hold-up and product for continuous wet ball milling of limestone at the solids feed rate of 1.36 kg/min and 62.5 wt% solids in the slurry [19]. Download : Download high-res image (199KB)

اObtener precio

Energy-Model and Life Cycle-Model for Grinding

2022.4.17 The median particle size of stirred ball grinding is X 50 = 17.62 μm for the feed limestone material. After wet grinding of 20 min in the laboratory stirred ball mill, the median particle size of ground limestone is

اObtener precio

TECHNICAL SPECIFICATION OF WET BALL MILL

2022.3.29 The Gravimetric feeder feeds limestone to Wet ball mill system. The Wet Ball Mill system consists of Wet Ball Mill, Wet Ball Mill Lubrication system, Mill circuit tank

اObtener precio

Population balance modeling approach to determining the mill

2022.1.1 In this paper, we investigate how the ball size distribution and size distribution of the particulate contents of the mill affect the mill diameter scale-up factor

اObtener precio

A Technical and Economic Comparison of Ball Mill Limestone

2021.10.13 In South Africa, Eskom’s Kusile Power Station utilizes conventional wet ball milling to grind high-grade limestone (96% CaCO 3) to 95% passing 45 µm prior to

اObtener precio

A study of the grinding of magnetite/limestone mixture in a

2021.9.1 1. Introduction The grinding process, providing the desired size of particles and the desired degree of liberation, is the preparation for separation in the mineral

اObtener precio

Particle size distribution and structural changes in limestone

2014.1.10 The dry grinding of limestone in a planetary ball mill was investigated as a function of the diameter of the grinding balls and the revolution speed of the mill. The

اObtener precio

Optimization of Ball Mill Grinding of a Limestone-Type

2023.4.13 Its performance depends on the mill diameter, mill length, mill operating speed, diameter and weight of grinding media, larger feed particle size and feed size

اObtener precio

Particle size distribution and structural changes in limestone

2013.1.1 The experimental mill used was a laboratory size of 209 mm diameter, 175 mm length, providing a total mill volume of 6001 cm3, with a total mass of 5.6 kg of steel

اObtener precio

A Technical and Economic Comparison of Ball Mill Limestone

2021.10.13 Request PDF A Technical and Economic Comparison of Ball Mill Limestone Comminution with a Vertical Roller Mill Wet flue gas desulfurization (WFGD),

اObtener precio

Ball Mill Particle Grinding - Union Process

CL Attritors – Stirred Vertical Ball Mill Limestone Grinding System The economical CL Attritor Stirred Vertical Ball Mill is used for wet grinding limestone for flue gas desulphurization. The process uses limestone feed stock of approximately 6mm in size and wet grinds the limestone to 95% minus 325 mesh. The CL Attritor operates in continuous

اObtener precio

Optimization of Ball Mill Grinding of a Limestone-Type

2023.4.13 The effect of ball size and interstitial filling on the performance of dry ball mill grinding was investigated for a limestone-type brecciated uranium ore. The optimum grinding was obtained with the combination of different balls (12.7–37.5 mm) and interstitial filling of 50% (20% ball filling ratio at fixed material filling ratio = 4%). The net power

اObtener precio

A Technical and Economic Comparison of Wet Milling

2021.5.20 3) from Idwala Lime’s Danielskuil mine site at a top size of 19 mm and work index of 12 kWh/t. The limestone is stockpiled and conveyed to a feed preparation area where conventional wet ball milling (in closed circuit with a classifier cyclone cluster) is used to reduce the limestone particle size to 95% passing 45 µm.

اObtener precio

GitHub

for cement plant size of limestone feed to product Normal Size Of Limestone Used For Cement Production Manufacturing process Lafarge Cement,concrete. How to Choose the Correct Siz

اObtener precio

crusher/sbm ball mill for limestone grinding power.md at

Contribute to yunan88/crusher development by creating an account on GitHub.

اObtener precio

Limestone Milling Process - Gravel Mill

The ball mill is intended to grind limestone, which is a rather soft material, to the desired fineness. The grinding and crushing of the limestone particles is done by the grinding medium, which are typically steel balls, inside the ball mill. Depending on the size of the limestone feedstock, several sized ball mills may be used to grind the ...

اObtener precio

PROJECT NTPL 2x500 MW PROJECT, TUTICORIN FGD

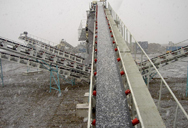

2022.7.19 1.2 Rated capacity of wet ball mill, kg/h 15,000 2.0 FEEDER 2.1 Type of feeder Gravimetric 2.2 Number of feeders Two (1W + 1S) 2.3 Capacity of feeder, kg/h 18,000 3.0 REVERSABLE BELT CONVEYOR 3.1 Number of feeders One (1W) 3.2 Rated Capacity, kg/h 15,000 3.3 Design Capacity, kg/h 18,000 4.0 Input Limestone size, mm

اObtener precio

TECHNICAL SPECIFICATION OF WET BALL MILL

2022.3.29 TECHNICAL SPECIFICATION OF WET BALL MILL EQUIPMENT (SUB ASSEMBLY OF FGD SYSTEM) 03 18.03.2022 P V S BABU AMAN KHRK 02 02.07.2021 P V S BABU AMAN KHRK 01 20.07.2020 P V S BABU AMAN SG ... The purpose of this system is to grind lump limestone of Size 25 mm (Max) to powder and for preparation of

اObtener precio

Particle size distribution and structural changes in limestone

2014.1.10 The dry grinding of limestone in a planetary ball mill was investigated as a function of the diameter of the grinding balls and the revolution speed of the mill. The tests were carried out with the same feed size (75 ... Grinding kinetics of quartz and chlorite in wet ball milling. Powder Technology, Volume 305, 2017, pp. 418-425.

اObtener precio

A cement Vertical Roller Mill modeling based on the

2022.10.1 Vertical roller mills (VRM) are widely used to grind, dry, and select powders from various materials in the cement, electric power, metallurgical, chemical, and nonmetallic ore industries. For the sectors above, the VRM is a powerful and energy-intensive grinding field [1], [2]. It is used to grind slag, nonmetallic ore, and other block

اObtener precio

sbm/sbm limestone size vs mill grinding.md at main

Contribute to dihog/sbm development by creating an account on GitHub.

اObtener precio

mill/sbm ball mill design for limestone.md at main crush2022/mill

Contribute to crush2022/mill development by creating an account on GitHub.

اObtener precio

Particle size distribution and structural changes in limestone

2013.1.1 The highest Si value obtained for calcite was 0.86 min−1 for the −850+600 μm feed fraction, while it was 0.42 min−1 for the −300+212 μm feed when 26-mm ball sizes were used in the mill ...

اObtener precio

A Technical and Economic Comparison of Wet Milling

2021.5.20 3) from Idwala Lime’s Danielskuil mine site at a top size of 19 mm and work index of 12 kWh/t. The limestone is stockpiled and conveyed to a feed preparation area where conventional wet ball milling (in closed circuit with a classifier cyclone cluster) is used to reduce the limestone particle size to 95% passing 45 µm.

اObtener precio

Ball Mills - 911 Metallurgist

2017.2.13 CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.

اObtener precio

en/ball mill limestone.md at main dinglei2022/en

Contribute to dinglei2022/en development by creating an account on GitHub.

اObtener precio

mill/sbm ball limestone crushers.md at main crush2022/mill

Contribute to crush2022/mill development by creating an account on GitHub.

اObtener precio

Enhancing the recovery of gypsum in limestone-based wet

2017.7.1 Generally, these ball mills consist of a rotating drum loaded with steel balls that crush the limestone by the action of the tumbling balls as the cylindrical chamber rotates, until obtaining a size less than 3 mm. From the above, it is evident that limited information in terms of improvement of limestone characteristics by means of suitable ...

اObtener precio

sbm/sbm ball milling method for limestone.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

اObtener precio

Optimization of Ball Mill Grinding of a Limestone-Type

2023.7.13 A ball mill is an equipment that is extensively used for grinding in the Mineral Processing Industries. Its performance depends on the mill diameter, mill length, mill operating speed, diam-eter and weight of grinding media, larger feed particle size and feed size distribution (FSD), feed rate, liner prole, sol-

اObtener precio>> Next: Mina Portátil Chancadora De Piedra

Mas noticias

- molinos cuchuqueros en cali

- trituradoras de piedra usadas en la india

- eficiencia del molino de bolas horizontal en oro y plata

- Movil de trituradora de piedra

- eslabon agricola de la manzana

- equipo mezclador de pulpa de mineral de del tanque de mezcla con bajo

- mineria planta procesadora de tierras raras

- maquina de aluminio en polvo

- raymonds molinos fabricantes en india

- nuevo molino de bolas rejilla humeda

- trituradora de recogida de arena

- plantas de trituración de granito europeos

- molinos de trigo en escoria

- con tornillo sin fin

- la mayoría de profesionales de piedra de corte de la máquina para las chancadorass de piedra caliza

- distribuidores de trituradora de mandíbula pe en Estados Unidos

- tamaro banco de trituradora de mandibula de mineral de oro para la venta

- Mini bentonita equipo de molienda en la India

- coal belt conveyor indonesia

- manual del usuario de la trituradora de cono para trituradora papeleria

- Planos Trituradora Una

- gp100 reglamento de funcionamiento de la trituradora de cono

- malla alambre canteras

- Planta procesadora de cromita y la máquina de separación en venta en Zimbabwe

- Dura Trituradora Piedra

- trituradoras de tierra en argentina

- materia prima detalles

- separador de rampa en espiral para la maquina de equipos de oro

- pequentildea maacutequina de fundicioacuten de oro

- diferentes principios de funcionamiento de la trituradora de mandíbula