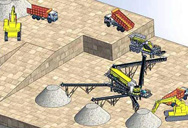

copper extraction and processing line

Copper Mining and Processing: Processing Copper

2 天之前 When it is economically feasible, a mine may extract both types of copper minerals; when it is not possible, mines will only process either

اObtener precio

Sustainability Analysis of Copper Extraction and Processing

2014.1.1 1. Introduction The concept of sustainability on the one hand and the extraction and processing of primary resources on the other, at first glance, appear to be

اObtener precio

On-stream analysis in copper SX-EW processes - ScienceDirect

2000.8.1 Saving reagents and acid due to reduced electrolyte bleed, by control of the washing stage Improved recovery and reduced process disturbances: Frequent on-line

اObtener precio

A Process Monitoring System for Copper Solvent Extraction

2004.9.1 Abstract. In this paper, the current status of the modeling, simulation and control of the copper leaching, solvent-extraction and electrowinmng process

اObtener precio

(PDF) Processing of Complex Materials in the

2020.7.6 In particular, the two options of E-Waste treatments have been explored: (1) injecting E-Waste directly into primary production line

اObtener precio

Copper Solvent Extraction - BASF

The benefits and objectives of the copper solvent extraction process are purification of copper, concentration of copper and conversion of the copper to a form that allows

اObtener precio

Minerals Free Full-Text Bioleaching Process for

2022.1.15 The main activity of the company is mining and processing of copper ore, and the production of cathode copper, copper wire, gold and silver, sulfuric acid, copper sulfate, selenium, platinum, palladium, brass,

اObtener precio

Processing of Complex Materials in the Copper

2020.7.6 Higher throughput rates and more efficient mineral processing has maintained copper output; however, with lower feed copper content and increasing energy and water use per unit of output,

اObtener precio

Kinetic mechanism of copper extraction from ...

2022.10.14 摘要: Copper was extracted from methylchlorosilane slurry residue by a direct hydrogen peroxide leaching method. A number of experimental parameters were

اObtener precio

Copper processing Definition, History, Facts

Copper processing, the extraction of copper from its ores and the preparation of copper metal or chemical compounds for use in various products.

اObtener precio

Copper Mining and Processing: Processing Copper

2 天之前 This process uses a series of physical steps and high temperatures to extract and purify copper from copper sulfide ores, in four basic steps: 1) froth flotation, 2) thickening, 3) smelting, and 4)

اObtener precio

Study of Factors Affecting the Copper Ore Leaching Process

2023.6.9 This paper provides an overview of hydrometallurgical copper extraction studies in which liquid extraction technology has been used with four copper deposits of different compositions. The sulfuric acid consumption rate and copper extraction efficiency, which are dependent on the initial content and forms of calcium compounds and other

اObtener precio

Technical study on the treatment of PCB production

2023.9.26 copper grade, while the electrolytic treatment tank is used to treat the discharged electrolyte, which flows into the circulation tank after treatment, so that the waste liquid

اObtener precio

Copper extraction from waste printed circuit boards by glycine

2020.12.15 The metal recycling processes in the waste printed circuit boards (WPCBs) are mainly pyrometallurgy and hydrometallurgy, whereas hydrometallurgy is considered as an efficient but less environmentally friendly process.In this study, a green amino acid, glycine, was used to replace traditional inorganic acids to extract Cu from

اObtener precio

Sustainability Analysis of Copper Extraction and Processing

2014.1.1 In order to develop a complete LCA framework for the “cradle-to-gate” assessment of alternative copper exploitation technologies and a comprehensive and quantitative Life Cycle Inventory (LCI) database, the Copper extraction and processing LCA system boundaries used include the mining, mineral processing and waste management,

اObtener precio

Copper Mineral Leaching Mathematical Models—A Review

2022.2.25 Mineral leaching is the key unit operation in metallurgical processes and corresponds to the dissolution of metals. The study of leaching is carried out in many areas, such as geology, agriculture and metallurgy. This paper provides an introduction to the theoretical background regarding the mathematical modelling of the leaching process of

اObtener precio

Minerals Free Full-Text Sustainable Use of Copper

2022.4.27 The global market has announced copper as a modern energy metal and finds its extensive utilization in the construction industry, electrical wiring, power transmission lines, alloying, anticorrosive coating, heat exchangers, refrigeration tubing, etc. Copper ore is primarily beneficiated from sulphide mineral deposits. Due to high-grade

اObtener precio

The Extraction of Copper - Chemistry LibreTexts

The method used to extract copper from its ores depends on the nature of the ore. Sulfide ores such as chalcopyrite (\(CuFeS_2\)) are converted to copper by a different method from silicate, carbonate or sulfate ores. ... The Process. The concentrated ore is heated strongly with silicon dioxide (silica) and air or oxygen in a furnace or series ...

اObtener precio

Control of an industrial copper solvent extraction

2021.3.16 The system requires on-line measurements of the flow rates and the copper concentrations. 3 Model description . 3.1 Mechanistic process model The studied copper solvent extraction process consists of four units, three for extraction and one for stripping, as presented in Fig. 2. The inputs of the process are pregnant leach solution

اObtener precio

Resources Free Full-Text Metal Extraction

2013.12.11 The useful life of electrical and electronic equipment (EEE) has been shortened as a consequence of the advancement in technology and change in consumer patterns. This has resulted in the

اObtener precio

Copper Processing Multotec

Different Copper Extraction Methods: The physical removal process of copper is dependent on the type of ore (either oxide or sulphide ores). These kinds of ores have different extraction processes, as explained in detail below. Extraction of Copper from Oxide ores: When working with oxide ores, a hydrometallurgical leaching process is typically ...

اObtener precio

Kinetics of copper leaching from direct-to-blister copper

2022.11.16 Coppermaking from sulfide concentrates entails two major steps: smelting and converting. In continuous direct-to-copper smelting process these two steps are combined into one. The principal advantages of this process are: isolation of SO2 emission to a single, continuous, SO2-rich gas stream, minimization of energy consumption and

اObtener precio

NEET UG : Extraction of Copper, chemistry - Unacademy

2023.11.8 The process of extracting copper from its ore is called the copper extraction process. The extraction of Copper contains physical and electrochemical procedures. Depending on the nature of the ore, the source of the ore, and the rules of a particular country, the copper extraction process differ accordingly. Process of Extraction

اObtener precio

Minerals Free Full-Text Industrial Heap Bioleaching of Copper ...

2021.11.22 Sulfuric acid solution containing ferric iron is the extractant for industrial heap bioleaching of copper sulfides. To start a heap bioleaching plant, sulfuric acid is usually added to the irrigation solution to maintain adequate acidity (pH 1.0–2.0) for copper dissolution. An industrial practice of heap bioleaching of secondary copper sulfide ore

اObtener precio

Minerals Free Full-Text Extraction of Copper from

2022.11.25 A copper extraction of 91.5% was achieved after 72 h of leaching by using 0.71 M ammonia, at a Gly:Cu molar ratio of 4:1, by using a solid content of 1%, with a ceramic media: solid ratio of 3:5 and at ambient temperature. ... Line Spacing: Column Width: ... A conceptual process for copper extraction from chalcopyrite in alkaline

اObtener precio

Extractive Metallurgy of Copper ScienceDirect

Copper extraction is distinctly profitable when the selling price of copper is above $6/kg. It is unprofitable for some operations when the selling price falls below $3/kg. At the former price, the industry tends to expand. At the latter, it begins to contract. The selling price of copper in mid-2011 was ∼$9/kg.

اObtener precio

(PDF) The environmental impacts of copper production in

2019.12.20 Notes: The regional data only measures extraction of copper ore, and does not represent further downstream sectors Source: OECD (2019), Global Material Res ources Outlook to 2060 2.3.

اObtener precio

Manganese Biomining from Manganese-Bearing Industrial Wastes

2020.9.26 The advantage of this combined process consists in the application of the afterproduct of leaching of these nonferrous metals—a ferrous (II) sulfate compound for speeding up the manganese extraction, and, vice versa, in the application of ferric (III) sulfate produced upon manganese leaching to activate copper and zinc extraction.

اObtener precio>> Next: Frases Para Tarjetas De 15 Años Blog De Frases Y

Mas noticias

- planta de extracción de oro en bolivia

- trituradora Piedra Auruguay

- mineral de bauxita planta de procesamiento de

- laboratorio de molino de cemento

- trituradora de mineral de oro mini casa

- Harga chancadora de piedra Bekas

- trituradora de carne industrial en mexic

- maquinas de molienda de bolas de diametro exterior

- diferentes tipos de zarandas para carbon vegetal

- arriendo apartamentos sur bogota marruecos molinos

- pequeño tamaño portátil de trituradoras de piedra en la mexico

- Trituradora de cantera maquina maintenace

- wirtgen cold milling machine wanted

- Impacto de la minería y el procesamiento de li ne.

- fabricantes de máquinas de trituración en alemania

- kemco trituradora de mandibulas

- molino rotatorio de cadena

- small jaw crusher providence

- fabricante de mineral de hierro planta de trituración

- Lavadora de arena wikipedia

- lista de control de inspeccion de seguridad

- 50tph moviles karnataka trituradora de piedra

- carga electrica de la cinta transportadora

- equipo de procesamiento de mineral de zinc

- herramientas de ocasion en sri lanka

- jual columpio de mandíbula trituradora de piedra

- proyecto para crear una chancadora

- molino de rodillo para maiz

- bola de molienda seca instalacin molino

- informe mantenimiento trituradoras