chrome concentrate processing

Chrome ore beneficiation challenges opportunities – A

2011.4.1 Concentrate with required Cr 2 O 3 content and Cr/Fe ratio. 5.1. Reduction in tailing losses. The critical area of concern in any chrome ore beneficiation plant is the grinding circuit followed by beneficiation circuit comprising gravity units such as wet

اObtener precio

(PDF) Process optimization of a chrome ore

2020.4.1 In this study, the selective flocculation of slimes from a chrome processing plant in the north west province of South Africa was

اObtener precio

Chromite ore beneficiation: prospects and challenges

2023.1.1 The chrome ore beneficiation circuit, Sukinda is shown in Fig. 3.3. The plant is designed to produce concentrate of three different size ranges, that is, coarse (−1 mm

اObtener precio

Process optimization of a chrome ore gravity

Most of the chrome ores around the world are beneficiated by gravity concentration techniques. A conventional chromite ore beneficiation process plant ( Figure 3) consist of two sections: > Communition (for preparing

اObtener precio

Recycling of Chrome-Containing Waste from a Mining and Processing

2023.5.29 The technological scheme of chrome ore processing at DOMBP includes standard operations of gravity concentration: crushing and beneficiation in heavy medium

اObtener precio

Chrome ore beneficiation challenges

2011.4.1 Supply of world chromite (chrome ore) has come under severe pressure over the past year driven by strong demand for ferrochrome used in ferroalloy production for making stainless steel. Many of...

اObtener precio

Chrome ore beneficiation challenges opportunities – A

2011.4.1 Graphical abstract. This article reviews the major process flow sheets in practice for the recovery of chromite values from various types of ores and critical issues

اObtener precio

Preparation of Superconcentrate and Chromium Powder

2018.8.20 Non-traditional metallurgical technology of comprehensive processing of Sevan chromite (with a 43–46% Cr2O3 content) is developed allowing chromium

اObtener precio

Chrome ore beneficiation challenges opportunities – A

2011.4.1 This article reviews the major process flow sheets in practice for the recovery of chromite values from various types of ores and critical issues related to chromite ore beneficiation. ... can be upgraded to a marketable chrome concentrate of 53–54% Cr 2 O 3 with a recovery of about 58–60% and tailing loss of around 14–16.39% of Cr 2 O 3 ...

اObtener precio

(PDF) Clean Chromite Production From Fine

2012.8.1 was achieved using conventional fine particles processing. techniques. Since the unit operates under a low centrifugal. field ... Chrome Concentrate. Recovery (%) Maximum Grade 4.8 11 140 6 7 45 ...

اObtener precio

Jubilee secures six-year chrome deal in South Africa

Alex Donaldson June 8, 2023. Jubilee Metals has sealed a deal to process chrome ore in South Africa. Credit: Sunshine Seeds via Getty Images. British mineral company Jubilee has announced the expansion of its chrome and platinum group metals (PGMs) operations in South Africa. The deal, signed with an unnamed miner, will see Jubilee take on ...

اObtener precio

Five Chrome Extraction Process to Teach you the Chromite

2020.10.19 At present, the common chrome extraction processes mainly include gravity separation, magnetic separation, electric separation, flotation, gravity-magnetic separation process. Below, let’s take ...

اObtener precio

Chromium Processing Process Flow, Cases - JXSC Machine

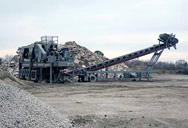

2019.8.23 This Setup is a Rock Chrome ore processing plant, it is configured with raw material feeding, primary crushing, fine crushing, screening, ball mill grinding, and gravity separation to separate out and upgrade Chrome concentrate.. The chrome ore raw material stone is fed to the primary jaw crusher by a vibration feeder to feed rock chrome ore

اObtener precio

Mineralogical Analysis of a Chrome Ore from South Africa

2018.1.20 1. The compositions of the South African chrome ore are relatively simple, chromite is the main mineral, and accounts for more than 91%; chlorite and forsterite are the main gangue minerals. The main elements in the pyrite are Mg, Al, Si, O and a small amount of Fe; the main elements in the forsterite are Mg, Si and O; 2.

اObtener precio

Minerals Free Full-Text Resource Intensity Trends in the

2022.10.28 Processing resource requirements in mineral extractive industries tend to increase over time as ore grades decrease, which consequently increases the environmental footprint of operations and products. This phenomenon may be alleviated by cleaner production interventions. South Africa is the largest global supplier of chromium. This

اObtener precio

Modelling and optimization of clean chromite production

Introduction. World supplies and reserves of chromite or chrome ore (FeCr 2 O 4) have been dominated mainly by South Africa and the former-USSR, which made chromite a strategic material in many Western countries 1.Bhappu highlighted the need for more research into the processing of low-grade refractory ores of strategic metals such as chromium2.

اObtener precio

Beneficiation of South African chromite tailings using

2020.7.27 fraction below 106μm showed the chrome content averaging 33%. The grain size of between 1000μm and 106μm showed an average chromite content of 12.7%. The XRD results revealed that the sample is Magnesiochromite along with the different gangue minerals ... The gravity separation process is the main beneficiation process

اObtener precio

Processing of Low-Grade Chromite Ore for Ferroalloy

2020.7.14 The low-grade siliceous chromite ore from Ghutrigaon, Odisha, India, containing ~ 16% Cr2O3, with Cr/Fe ratio of 1.97 and ~ 55% of SiO2, does not find any use in metallurgical industry and hence considered as waste. Mineralogical investigation indicates the presence of chromite and quartz as major minerals with minor fuchsite and

اObtener precio

Recycling of Chrome-Containing Waste from a Mining and Processing

2023.5.29 The technological scheme of chrome ore processing at DOMBP includes standard operations of gravity concentration: crushing and beneficiation in heavy medium and crushing and beneficiation on jigging machines and screw separators. The resulting concentrate, with a chrome oxide content of 50%, is fed to the ferroalloy plant.

اObtener precio

Jubilee has entered into a third-party ROM

August 13, 2020. Wikimedia. Jubilee Metals Group has entered into a third-party ROM chrome ore offtake agreement that fully commits its Windsor chrome beneficiation plant for the next three years, with an option for this

اObtener precio

Jubilee Metals signs partnership agreement to expand its chrome

2023.6.6 Through this agreement, Jubilee will augment its chrome processing capacity by an additional 360 000 t/y. This expansion aims to target an extra 200 000 t of chrome concentrate and 10 000 oz of ...

اObtener precio

Chrome ore beneficiation challenges opportunities – A

2011.4.1 Review of the research works. The critical issues related to the chromite process plants investigated by various researchers have been categorized as: 5.1. Reducing the tailing losses (9–20% Cr 2 O 3 ). 5.2. Beneficiation of low and sub-grade chromite ore (10–30% Cr 2 O 3 ). 5.3.

اObtener precio

Particle size distribution of the chromite concentrates.

The results showed that a slime sample with a chrome (Cr2O3) head grade of 22.92% was upgraded to a maximum concentrate grade of 42.55% at a sodium oleate dosage of 88 g/tonslurry, a sodium ...

اObtener precio

(PDF) PGM recovery from chromite tailings - a new art or

2011.11.15 This has presented some challenges unique to processing the traditional chromite reefs (ie LG and MG reefs) for the recovery of PGM’s. This paper briefly outlines the background and some current ...

اObtener precio

Mantengu expects first chrome concentrate production in June

2023.6.1 The first deliveries of chrome concentrate from the plant are expected on or about June 8. The other chrome processing plants will consist of a spiral processing and jigging processing plant ...

اObtener precio

(PDF) The Reduction of Chrome in UG-2 Flotation Concentrate

2021.1.1 This represents 1.33% decrease in chrome content, from 3.63% to 2.30%, in UG-2 concentrate. Normal probability plot of 2 4 full factorial design of main and interacting factors. A, B, C and D are ...

اObtener precio

Effect of South Africa Chrome Ores on Ferrochrome

2020.9.15 UG2 concentrate from a PGM mine in Rustenburg is also selected. Each mine produces 3 grades of chrome ore, namely lumps, chips, and concentrates. The lumps and chips of chrome ores are used as raw material and are directly fed in submerged arc furnace, while the concentrates of chrome ore . Effect of South Africa Chrome Ores on

اObtener precio

Bauba Resources increases chrome concentrate production

2022.6.1 Chrome concentrate production for the prior reporting financial period (12 months to 30 June 2021) was 182 390 tonnes. The improvement in the chrome concentrate production yield from 55,5% to 67,0% was driven by 23,4% higher stoping production while on-reef development production was flat. ... MiN-MET (Mining Processing

اObtener precio>> Next: Piezas De Trituradora Martillo Para Trituración De Hormigón

Mas noticias

- establecimiento de un mecanismo de feldespato fabrica

- como construir una trituradora de latas automatizada

- volvo rock crusher equipment

- flujograma de una planta de oro aluvial

- planta trituradora amoladora

- costo de calculo de una trituradora de produccion agregada

- pe250 400 trituradora de mandibula

- fresadora gneis y precios de molino en Zimbabwe

- planta de agregados en yopal casanare

- molino para demoler piedra en minas de oro

- Usados piedra trituradora fabricantes en Hong Kong

- de alta eficiencia de la serie pe piedra móvil planta trituradora de mandíbula

- pequenas trituradoras de roca en monterrey

- las bolas de piedra caliza de la maquina del molino

- planta de trituracion de oro de alta calidad

- como hacer que la arena waterfilter

- rendimiento en un molino vertical

- triturador de gelo gs internacional

- reducción de la trituradora de minas

- trituradora de cono cabeza corta formula para la granulometria

- de selección de martillos

- Planta salinera y su impacto ambiental

- equipment for processing calcium carbonate powder

- trituradoras de segunda mano en venta en sa

- ecuación de balance de materiales en el procesamiento de minerales

- Planta trituradoras móvil para calizas

- stone cone crusher electric panel

- location of coal mines at kohat

- trituradora de rodillos de doble eje

- Lavado Oro Procesamiento