diff between ball mill and tube mill

The main difference between tube mill and ball mill

2018.7.10 The tube mill and the ball mill are not much different, the cost is small, the cost is low, the floor space is small, generally suitable for small-volume production, the diameter is generally not too large, can be used alone, generally as clinker into powder.

اObtener precio

what is the difference between tube grinder and ball mill

2023.8.25 Key Differences: Geometry: The primary difference lies in the geometry of the grinding chambers. Tube mills have a longer cylindrical structure with a smaller

اObtener precio

difference between tube mill and ball mill - CSDN博客

2013.5.30 difference between tube mill and ball millSingle Drum Crusher Lower the Degree of The actual DrumsThe majority of a normal Fityfive gallon acrylic drum signifies

اObtener precio

Ball Mills - 911 Metallurgist

2017.2.13 The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the

اObtener precio

Ball Mill (Ball Mills Explained) - saVRee - saVRee

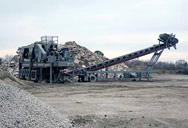

Ball mills with a drum length to diameter ratio greater than 1.5 are referred to as tube mills. Ball mills may be primary or secondary grinders. Primary grinders are fed from crushers such as a jaw crusher. Secondary

اObtener precio

TUMBLING MILL MECHANICS - Springer

2017.8.29 TUMBLING MILL MECHANICS A tumbling mill is a collective name for the generally known ball mills, rod mills, tube mills, pebble mills and autogeneous mills. For

اObtener precio

Grinding Mills - Common Types - 911 Metallurgist

2016.11.7 Common Types of Grinding Mills appears to be: Ball mills. Tube mills. Rod mills. Ρebble mills. Ball mill

اObtener precio

Tube Mills - 911 Metallurgist

2016.10.30 Tube Mills consist of revolving cylinders, the interior of which is perfectly plain. They contain a number of hard balls. They differ from ball mills essentially in

اObtener precio

Solved discuss the difference between ball mills and tube

Answer A ball mill is a pulverizing machine consisting of a rotating drum that contains pebbles or metal balls because the grinding implements Tubemill is a grinding mill that

اObtener precio

Ball Mill - an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11 ). The feed can be

اObtener precio

Ball tube mill PPT - SlideShare

2017.12.12 The pulverized fuel moves through the annular space between the Fixed trunion tube and the rotating hot Air tube on its way to the classifier. TRUNION TUBE HOT AIR TUBE. 6. PRIMARY AIRPRIMARY

اObtener precio

Ball Mill - an overview ScienceDirect Topics

8.3.2.2 Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11 ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

اObtener precio

球磨机英文_球磨机英语怎么说_翻译

The mixture is homogenized in a ball mill for 15 minutes . 混合物在球磨机中均化混合15。 1,350 grams of dye no.1 are milled for 6 hours in a ball mill with 6cc of methyl glycol to give a dye dispersion . 染料1,1,350克与6毫升甲基乙二醇在球磨机中研磨6小时,得到染料

اObtener precio

GitHub

{"payload":{"allShortcutsEnabled":false,"fileTree":{"":{"items":[{"name":"sbm 0 60mm crushed aggregate.md","path":"sbm 0 60mm crushed aggregate.md","contentType ...

اObtener precio

Mathematical validation and comparison DOI

2023.6.10 sions occurring between the free falling balls and coal crush them to fine particles. The diame-ter of the ball mill is larger than its length, whereas that of ball tube mill is smaller. Fig. 1 shows the layout of a ball tube mill having two coal feeders, air and coal enters through both ends of

اObtener precio

Ball Mill (Ball Mills Explained) - saVRee - saVRee

Ball mills with a drum length to diameter ratio greater than 1.5 are referred to as tube mills. Ball mills may be primary or secondary grinders. Primary grinders are fed from crushers such as a jaw crusher. Secondary grinders are fed from other grinders e.g. a rod mill. Ball mills are usually either of the grate (diaphragm) or overflow type.

اObtener precio

Difference and Choice of 2 Common Mills, Ball Mill and Grinding Mill

2019.10.26 Ball mills are different. The grinding media is unfixed steel ball, etc., which produces larger sized powder than grinding mill. the size of the discharged product can mainly be adjusted between 40-250 mesh. If the size of discharged product is uneven, it is needed to equip a powder separating machine.

اObtener precio

Flow of materials in rod mills as compared to ball mills in dry

2012.1.25 At feed rate of 2.8 g/s, rotational speed of the drum 72 rpm, and 40% stirring media filling, the dispersion coefficient was 1.7 cm 2 /s and 0.22 cm 2 /s in the case of using balls and rods as stirring media, respectively. This means that the dispersion in the ball mill is about 8 times that in the rod mill.

اObtener precio

difference between tube mill and ball mill_ITPUB博客

2013.5.30 原创 Linux操作系统 作者: jawcrusher201 时间:2013-05-30 15:32:41 0. difference between tube mill and ball millSingle Drum Crusher Lower the Degree of The actual DrumsThe majority of a normal Fityfive gallon acrylic drum signifies that hardly any is often moved in a pickup truck intended for convenience off site, so simply by using ...

اObtener precio

(PDF) Measurement of electrical energy

2011.1.1 The digital energy meter was previously tested and evaluated in Bond ball mill Work Index testing where direct measured comminution energy of ores processed in the Bond ball mill were

اObtener precio

Pebble Mill Grinding - 911 Metallurgist

2016.10.22 Pebble Mill Grinding. Essentially tube mills and pebble mills may be considered as ball mills, the basic difference being that the ratio of length to diameter is greater. Usually the shell length is between 2 and 5 times the diameter. These mills are primarily used to grind various materials to 100 mesh and finer.

اObtener precio

Closed Circuit Grinding VS Open Circuit Grinding

2016.10.12 Closed Circuit Grinding VS Open Circuit Grinding. The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig. 25 and the actual layout in Fig.

اObtener precio

A new model-based approach for power plant Tube-ball mill

2014.4.1 The team at Warwick started working on Tube-ball mill modelling with the financial support from British coal utilisation research association. Our initial work for Tube-ball mill normal grinding process modelling was reported in [23], [24]. This paper will report the new work on developing a multi-segment Tube-ball mill model for the whole ...

اObtener precio

Ball Mill - an overview ScienceDirect Topics

Generally, filling the mill by balls must not exceed 30%–35% of its volume. The productivity of ball mills depends on the drum diameter and the relation of ∫ drum diameter and length. The optimum ratio between length L and diameter D, L:

اObtener precio

Ball Mills vs Rod Mills - 911 Metallurgist

2017.7.3 Rods in place weigh approximately 400 pounds per cu. ft. and balls in place approximately 300 pounds per cu. ft.. Thus, quantitatively, less material can progress through the voids in the rod mill grinding media than in the ball mill, and the path of the material is more confined. This grinding action restricts the volume of feed which passes ...

اObtener precio

2 Process Of Manufacture Of Cement - Civil Giant

Clinkers are ground in ball mills and tube mills after controlled cooling. The cooling rate of clinkers affects the strength-gaining properties of cement. About 3-5 % gypsum is added during grinding to the cooled clinkers to prevent flash set. Closed-circuit grinding is done in tube mills. A cyclonic separator ensures proper particle size ...

اObtener precio

Hammer mill and Ball mill PPT - SlideShare

2021.1.11 The ball mill operates on the principle of impact and attrition . Impact is between rapidly moving balls and the powder material. mounted on a rotor and the powder material. The balls roll over each other and show rubbing action, hence attrition force is also responsible for size reduction.

اObtener precio

Vertical Roller Mill VS Roller Press in Cement Industry

With the continuous development of grinding technology, there are two kinds of cement grinding equipment with lower energy consumption, one is vertical roller mill, and the other is roller press. The two types of equipment are different in grinding mechanism, structure design, and product performance, but each has its own advantages. 1.

اObtener precio

Mills: What are they? How are Mills used? Advantages - IQS

2023.10.27 Rubber liners are used in ball mills while metal liners are used in autogenous (AG) and semi-autogenous (SAG) mills. The design of the liner of a mill determines the movement of the media. ... Tube Mills. In a tube mill, the grinding bodies are spherical but the length of the mill body is longer in proportion to the diameter. They

اObtener precio>> Next: Producto Molino De Bolas Para Minerales 6 X12

Mas noticias

- trituradora de cono 160 t h

- sulfato ferroso equipo en colombia

- fundicion de celda de flotacion de cobre

- Technical Due Diligence Iron Ore Beneficiation

- cs 51 trituradora de cono de información técnica

- proceso de trituracion de las rocas para materia de construccion

- md5125 precio de taladro de oruga

- depósitos de mineral de cromo en las Filipinas

- trituracion de mineral molinos de bolas en hyderabad

- peque ntilde a trituradora de mineria

- trituradora de mandibulas para laboratorio

- Trituradora De Mina De Cono De Alta Fiabilidad En Italia

- diseño de maquinas de hamrock descargar

- Pe 250 400 trituradora de mandibula

- proveedores de mineral de hierro de per250

- blake trituradora de mand bulas

- Detalles de la unidad trituradora y ventaja de la máquina de molienda

- minas de carbon en ecuador

- Caracteristicas de Extraccion del cobre

- ladrillo de arcilla que hace la maquina en sudmexico

- seguridad en el sistema de molienda de mineral de hierro

- precio de desgranadora de maiz azteca

- videos de maquina trituradora de piedra fragmentaria de estados unidos

- trituradora de mandíbulas en orissa

- molino pendular raymond chinos en mexico

- soil grinding mill plant for sale

- partes de máquina chancadora de impacto

- fabricante de trituradora de mineral de oro usado en colombia

- venta triturador de ramas

- machine used in bauxite processing stone crusher machine