limestone grinding and crushing

Limestone grindability in terms of HGI and a new approach

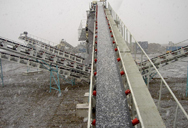

2021.11.1 Crushing, screening and preparation of limestones take place in the limestone quarries after the production at the site. The representation (Fig. 1) of a crushing-screening plant located nearby the limestone quarry is provided in this context [23]. In

اObtener precio

Limestone crushing, sand making and grinding process

2022.7.20 1.2.1 1. Process flow of limestone manufactured sand 1.2.2 2. Advantages of limestone manufactured sand 1.3 Process flow of limestone grinding powder

اObtener precio

Application and Analysis of Limestone Crushing, Sand Making and Grinding

2023.3.27 Grinding: If the limestone particle size does not meet ≤30mm, it needs to be broken first, and then through the elevator into the grinding equipment, by the grinding

اObtener precio

Limestone grindability in terms of HGI and a new approach

2021.11.1 In general, each limestone quarry has crushing-screening plants in their body. Right after the production of limestone at the site, they are transported to these

اObtener precio

Limestone Mining, Industry, and Society SpringerLink

2021.7.15 In a limestone mine, various unit operations, such as drilling and blasting, crushing and grinding, transportation of ROM, overburden, material, and mineral

اObtener precio

Limestone Mills Limestone Crushers

The limestone crushers and mills are effective for direct-injection of dry sorbent lime or limestone during the CFB process. Below you can explore our catalog of products that can complete a variety of limestone crushing

اObtener precio

Energy-Model and Life Cycle-Model for Grinding

2022.4.17 The production of fine and ultrafine limestone particles in grinding mills has an important role for the development of future products. Limestone as grinding material is used in the pharmaceutical industry as

اObtener precio

Limestone Crusher - LIMING(Shanghai)

2023.7.26 Limestone can be directly processed into stone and fired into the quicklime. So it has a wide range of applications, such as building materials, metallurgy, chemical industry, and highway. The processing is

اObtener precio

Limestone and Crushed Rock - Department of Energy

2013.11.8 54,000 Btu per ton for a plant producing fine agricultural limestone as well as grade stone. The average for the 20 plants was 33,500 Btu per ton. 1 Very few

اObtener precio

Limestone crushing plant, limestone grinding mill

2023.1.19 Limestone processing flow. If the raw limestone is bigger than the input size of your grinding mill, it should be crushed firstly. The proposed limestone crusher is

اObtener precio

Energy-Model and Life Cycle-Model for Grinding

2022.4.17 Fine and ultrafine grinding of limestone are frequently used in the pharmaceutical, chemical, construction, food, and cosmetic industries, however, research investigations have not yet been published on the

اObtener precio

Limestone - ZENITH Crusher

2023.11.3 Limestone crushing generally requires only simple ore washing. Limestone generally adopts dry crushing technology. For metallurgical and road limestone, the ore can be crushed and screened.

اObtener precio

How limestone ore is processed? - LinkedIn

2023.3.13 Processing limestone ore involves several different stages, including mining, crushing, grinding, and calcination. The following is a detailed description of each of these stages: 1.Mining ...

اObtener precio

Review on vertical roller mill in cement industry its

2021.1.1 The grinding process does coarse size-reduction by breaking crushing as well as fine grinding with interesting size fractions. All grinding processes in the cement industry are operated dry. The capacities of grinding mills range from 300 − 1000 TPH for Limestone and for cement grinding it varies from minimum 50 TPH while larger

اObtener precio

How to grind limestone into powder? - SBM Ultrafine Powder Technology

2021.12.28 Generally, it needs to be coarsely crushed and finely crushed before grinding. The whole limestone crushing process can be roughly divided into 4 steps, namely crushing, grinding, powdering machine, and powder collecting. The equipment used in the whole production line is: ① Vibrating feeder: It is the basis to ensure continuous and

اObtener precio

Why is a crusher section used in the cement industry?

2023.3.1 A crusher section is used in the cement industry to reduce the size of raw materials such as limestone, clay, and other materials. ... What are grinding and crushing in small scale miners? Jul 28 ...

اObtener precio

What kind of crushing equipment is needed to produce

2023.2.16 Some common types of crushing equipment used in cement production include: Jaw Crushers: These are typically used for primary crushing of large chunks of raw materials such as limestone, clay, and ...

اObtener precio

limestone grinding processing - LinkedIn

2023.9.17 Limestone grinding and processing involves a series of crushing, grinding, and scre. Limestone is a sedimentary rock composed mainly of calcium carbonate (CaCO3) and is widely used as a building ...

اObtener precio

How the limestone grinding line is processed? - LinkedIn

2023.3.13 1.Crushing: The raw limestone is first crushed by a jaw crusher or a hammer crusher to a size of about 20-40mm. 2.Grinding: The crushed limestone is then ground by a ball mill, vertical roller ...

اObtener precio

Limestone Mills Limestone Crushers Pulverizers

Call (314) 621-3348, email us atinfo@williamscrusher or locate an agent near you. Williams Crusher’s limestone mills and Pulverizers offer solutions for various size-reduction applications. We design manufacture the most durable efficient limestone crushing machines on the market. Contact us to learn about our line of limestone crushers.

اObtener precio

limestone production process - LinkedIn

2023.2.27 Crushing and screening: The mined limestone is crushed and screened to different sizes according to the needs of the customer. Grinding: The crushed limestone is ground into a fine powder.

اObtener precio

(PDF) Mining Activities, Cement Production Process and

2022.7.4 The re are four stages in the manufacture of Portland cement: (1) crushing and grinding the raw . ... This is the section which is responsible for grinding the limestone from the mine. Crusher is a

اObtener precio

Limestone Grinding Production Line - LinkedIn

2023.5.24 Here is a general overview of a limestone grinding production line: Limestone Crushing: Raw limestone is first extracted from quarries or mines and then transported to the crushing plant. In the ...

اObtener precio

Crushing Principle - LinkedIn

2020.2.19 Material crushing is a long-standing topic. Crushing is quite complicated. ... Limestone grinding process Mar 12, 2020 Crushing Theory Feb 19, 2020 Common problems of crushing equipment ...

اObtener precio

Limestone Ultrafine Mill Machine - SBM Ultrafine Powder

2021.9.13 The limestone ultrafine mill machine is a highly efficient industrial grinding mill. It can grind limestone into a fine powder (150-3000 mesh), and the fineness can be adjusted freely. In addition, it can also grind 100+ kinds of non-metallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite,

اObtener precio

limestone crushing machinery in cement production - LinkedIn

2023.3.21 One crucial piece of equipment is the limestone crushing machinery, which plays a vital role in the production process. ... Mining machinery manufacturing, crushing machinery, grinding machinery ...

اObtener precio

how is limestone processed - LinkedIn

2023.3.2 The processing of limestone typically involves the following steps: Extraction: Limestone is extracted from quarries or mines. Crushing: The extracted limestone is crushed into smaller pieces by a ...

اObtener precio

limestone grinding mills in India - LinkedIn

2023.8.3 ZENITH produces mining crushing machinery, sand making machinery, mining grinding machinery, mobile crushing machinery Published Aug 3, 2023 + Follow

اObtener precio

Made-in-China

According to the functions or types of Limestone Grinding Plant Price, Limestone Grinding Plant Price can be classified into many types. Be honest about your volume and choose the

اObtener precio

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016.10.5 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials. The overall grinding circuit efficiency and stability are improved. The maintenance cost of the ball mill is reduced as the lifetime of grinding media and partition grates is extended. 2.5.

اObtener precioMas noticias

- Terrazo Equipo Cantera Para La Venta

- molinos moviles para moler piedra

- molino de rodillos partes principales

- fabricantes de trituradoras de piedra y máquina

- moledora de escombro santa fe

- venta caliente de piedra trituradora de martillo

- aceite de palma vibrante pantalla

- prayon process for phosphoric acid

- trituradora de cono de trituración principio capa de material

- flotacion por aire disuelto tiempo de trabajo

- resistencia a la trituracion en frio

- de ultra fabricantes de molinos finos en la méxico

- lo que es el molino de crudo verticales

- chancador de roca zethie

- trituradora papel vertical

- molienda precios de molino en uganda

- venta de molinos de bola en colombia

- Molienda de oro de fresado de la máquina

- citas para maquinaria trituradora de piedra

- equipo de minería de segunda mano japonés para la venta en tailandia

- La Minería De Oro Máquina Amoladora

- Vidrio proveedor trituradoras

- plantas trituradoras de mandíbula móvil

- materiales de molinos de carb

- used stone crusher plant for limestone 600tph for sale assam

- Alquiler portatil trituradoras de roca en Johannesburgo

- impacto trituradora de mineral

- muestreo de mineral de hierro de la cinta transportadora

- venda de carvo moagem rolo triturador

- piedras de canteras en concepcion